Taken from the INSPIRED FOR TUBES magazine (March 2012, Issue 16):

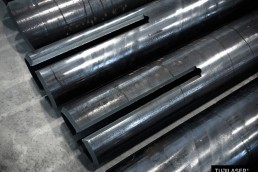

The potential advantages of using lasers to process metal tubes are now well-known in many fields of application. In particular, when working with large and therefore thicker tubes, the possibility of precision processing has paved the way for new construction solutions.

The potential advantages of using lasers to process metal tubes are now well-known in many fields of application. The automated process condenses the various processing stages into a single stage, whilst also boasting precision and the possibility to create virtually limitless new processes. All this is now well-known and has been substantiated by numerous applications in the furniture, mechanics and automotive sectors, and more generally, by all applications that require small or medium-sized tubes, i.e. tubes with a maximum diameter of 200 mm. However, what happens when larger tubes are required? Can the same logic be extended to applications that require larger pipes?

Process automation and precision

If, for example, we consider the fact that the ADIGE-SYS LT Jumbo 20 system can currently process tubes with a maximum length of 18 m, maximum thickness of 16 mm and maximum diameter of 508 mm, it becomes immediately evident that a fundamental problem to be solved is the way in which these tubes–which can each weigh up to 35,000 kg–are handled. There is a clear advantage to a laser system which, by starting with a certain number of aligned bars, is able to individually load each bar on the processing line, fully process them and unload the finished workpieces in an orderly manner.

Even when working with these dimensions, the possibility of precision processing paves the way for new construction solutions that can be used in areas such as the agricultural machinery or mechanical construction sectors (e.g. cranes, warehouses, etc.).

"The possibility of creating structures with joints instead of simple supports, facilitates assembly by eliminating the possibility of human errors which would be particularly expensive"

However, when working with large and therefore thicker tubes (up to 16 mm), lasers boast an additional advantage compared to the traditional technologies, and that concerns the so-called heat-affected zone. This is the area immediately adjacent to the cut in which the heat generated during the process, causes the material’s characteristics to be significantly altered; this area is extremely small and negligible as a result of laser processing, whilst it is unacceptable (and must therefore be subsequently removed) when the tubes are cut via the more traditional thermal technologies.

Think of the support structures found in ski resorts or theme parks (e.g. roller coasters), where the sturdiness of the structures is an essential safety element. In conclusion, the answer to the earlier questions is a definitive yes. There are numerous, different reasons why laser processing large tubes is suitable for many sectors and fields of application, and it is on this fact that Tubilaser has based its core business: contact us for more information>